EMERGENCY SERVICE

Heat Recovery Units

What are Heat Recovery Units?

Heat recovery units are advanced systems designed to improve energy efficiency by capturing and reusing heat from exhaust air. These units play a crucial role in modern buildings, contributing to reduced energy consumption and enhanced indoor air quality.

Definition:

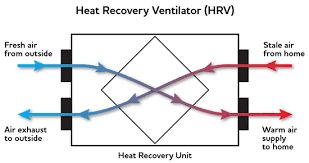

Heat recovery units are mechanical systems that transfer heat from the outgoing air to the incoming air, thereby reducing the amount of energy needed to heat or cool a building. This process is essential for maintaining a comfortable indoor environment while minimizing energy waste.

Functionality:

he primary function of heat recovery units is to recover heat from the air being expelled from a building and use it to precondition the fresh air coming in. This process involves a heat exchanger, which transfers thermal energy from one air stream to another without mixing the two air streams.

WHY CHOOSE US?

Benefits of Heat Recovery Units

Heat recovery units offer several advantages that make them a valuable addition to energy-efficient building systems.

Improving Energy Efficiency:

By recovering and reusing heat that would otherwise be wasted, heat recovery units significantly enhance the overall energy efficiency of a building. This results in lower energy consumption and reduced demand on heating and cooling systems.

Reducing Operational Costs:

The energy savings achieved through the use of heat recovery units translate into lower operational costs. Over time, the initial investment in these units is offset by the savings on energy bills, making them a cost-effective solution.

Environmental Impact:

Heat recovery units contribute to environmental sustainability by reducing the carbon footprint of a building. By decreasing the amount of energy required for heating and cooling, these units help lower greenhouse gas emissions and support greener building practices.

How Heat Recovery Units Work

Understanding the working principles of heat recovery units can help you appreciate their role in energy efficiency.

Basic Principles:

Heat recovery units operate on the principle of heat exchange. They use a heat exchanger to transfer thermal energy from the outgoing air to the incoming air. This process helps in preheating or precooling the incoming air, reducing the need for additional heating or cooling.

Key Components:

The main components of a heat recovery unit include the heat exchanger, fans, filters, and controls. The heat exchanger is responsible for transferring heat between the air streams, while the fans circulate the air through the system. Filters help maintain air quality by removing particulates and contaminants.

Choosing the Right Heat Recovery Unit

Selecting the appropriate heat recovery unit involves evaluating several factors to ensure it meets your specific needs.

Assessing Your Needs:

Consider factors such as the size of your building, climate, and ventilation requirements. Understanding your needs will help you choose a unit that provides optimal performance and efficiency.

System Size and Efficiency:

Ensure that the heat recovery unit is appropriately sized for your building. An oversized or undersized unit can lead to inefficiencies and increased energy costs. Look for units with high efficiency ratings to maximize energy savings.

Budget and Installation Costs:

Evaluate the cost of the unit and installation, keeping in mind that higher efficiency units may have a higher initial cost but offer greater long-term savings. Consider the return on investment and potential energy savings when making your decision.

Installation Process

Proper installation is crucial for ensuring the effective operation of heat recovery units.

Professional Installation vs. DIY: While DIY installation may seem cost-effective, professional installation ensures that the unit is correctly installed and optimized for performance. Professionals have the expertise to handle complex installations and ensure compliance with building codes.

Installation Steps and Tips:

The installation process typically involves selecting a suitable location for the unit, connecting it to the building's ventilation system, and ensuring proper sealing and insulation. Follow manufacturer guidelines and consult with professionals to ensure a successful installation.

Maintenance and Troubleshooting

Regular maintenance and troubleshooting are essential for keeping heat recovery units in good working condition.

Regular Maintenance Tips:

Perform routine maintenance tasks such as cleaning filters, checking for obstructions, and inspecting components for wear and tear. Regular maintenance helps ensure that the unit operates efficiently and extends its lifespan.

Common Issues and Solutions:

Common issues include reduced airflow, noise, and system malfunctions. Address these problems by inspecting the unit for blockages, ensuring proper component functioning, and consulting with professionals for repairs if needed.

Case Studies and Real-World Applications

Real-world examples demonstrate the effectiveness and benefits of heat recovery units in various settings.

Residential Success Stories:

Many homeowners have experienced significant improvements in energy efficiency and comfort by installing heat recovery units. Success stories often highlight reduced energy bills and enhanced indoor air quality.

Commercial Applications:

Businesses and commercial properties also benefit from heat recovery units. They help reduce energy costs, improve occupant comfort, and support sustainability goals in commercial settings.

FAQs about Heat Recovery Units

Heat recovery units are an excellent investment for enhancing energy efficiency, reducing operational costs, and supporting environmental sustainability. By understanding the different types of units, their benefits, and how to properly maintain them, you can make informed decisions that improve your home's comfort and efficiency.

Whether for residential or commercial applications, these units offer substantial long-term advantages, making them a valuable addition to modern building systems. Eagle Air can help you with a heat recovery unit.

Would You Like to Know More?

We have a simple mission, to become the best provider of HVAC services in the major metropolitan area. We have been working nonstop, providing excellent customer service at competitive prices. If you would like to know more about our services and our track record in your city, give us a call today!